Collections

News

News

Suppressors WERE hard to clean.

Here is a prime example of why I love the slip 2000 and proof it works. This picture is a before and after cleaning on a silencer baffle. I have over 500 rounds of 22lr fired thru this suppressor and last night I had to pound the baffles out with a hammer and I couldn’t scrape the carbon off with a knife, so I soaked it over night in the carbon killer, and the carbon build up pretty much wipes off making the baffle look brand new again. The picture doesn’t even do any justice, but it made the baffle a shinny stainless again. Never thought it was possible.

Thanks

Ethan Fonder Double Drop Gun Shop Badger SD

David B. Smith from Precision-Engineered Performance

Greg,

I just wanted to take a moment to relate my absolute satisfaction with all of the Slip2000 products I have had the pleasure of trying to date.

Your Carbon Killer has taken the drudgery out of cleaning all of my development guns, especially the .338 Lapua extra long range rifle. Carbon Killer is an amazing muzzle brake cleaner, which in the past was a job I did not look forward to.

I am now using your Slip2000 lubricants as a barrel treatment in all of my personal and development guns.

As the inventor of the Magnumlite carbon fiber barrel system as marketed by Magnum Research and the holder of the 3 patents relative to this barrel system, I am amazed at the performance of your lubes as barrel conditioners. As a barrel developer, I break in many barrels and have been more than elated at the shortening of this procedure and the resultant ease of cleaning your lubes provide.

I have found that the “clean cold bore” shot is always in the group when your lubricants are used in the bore. I have also found your lubes to be the most stable in the bore for long term storage as well. In the past, lubes have broken down and failed to perform as desired when rifles were stored for any lengthy period. I now do not have to worry about this issue.

I will continue to recommend your entire line of products to all of my clients, shooting associates and customers.

It is indeed a pleasure to find products that exceed the need.

Thanks again for all of your products and wonderful customer service.

I wish you and Slip2000 nothing but continued success.

Regards,

David B. Smith

Independence Training Uses Slip 2000

We train no matter what the weather conditions are, and at one particularly snowy handgun course the hazards of poor maintenance became apparent to some of our students. The temps had dropped below freezing and some of the liquid lubes and grease lubes began to stop up the guns.

We took a break, field stripped all guns, cleaned off the old lube with Slip 2000 725 cleaner, and then re-lubed all guns with Slip2000 EWL. It didn’t stop snowing, but the guns didn’t stop up again thanks to Slip 2000.

Glen Stilson Head Instructor Independence Training

MARINE CORPS CONTRACT EXPANDED

After a successful year of testing, evaluations, and usage, the US Marine Corps has expanded their contract with Slip 2000. They have recently installed 6 additional Slip 2000 Ultrasonic Cleaning Systems and will be adding 6 more in the next 30 days, with more to come. The sole source contract specifies that only Slip 2000 Equipment, Slip 2000 Lubricants and Slip 2000 Cleaners can be used.

The heated dual tank Ultrasonic Cleaning System allows multiple guns to be cleaned and lubricated quickly. One tank uses ultrasonic technology to clean a group of guns while the other tank simultaneously provides a lubricant and corrosion treatment to another group.

Before using this Slip 2000 Cleaning System, the Marine Corps used a solvent tank process that required 30 minutes to clean 1 weapon. By using the Slip 2000 Ultrasonic Cleaning System and Slip 2000 Gun Lube the Marine Corps was able to reduced this cleaning time from 30 minutes a gun to 5 minutes. An armory location using this system is capable of cleaning 400-700 weapons an hour.

This cleaning system has also greatly reduced the hazardous emission control fines and penalties accrued by other cleaning systems in use.

The Slip 2000 Ultrasonic Cleaning System is designed to provide both a safe and fast way to clean a large quantity of guns while also providing an excellent lubrication and corrosion protection treatment. A huge advantage to the system is the use of Slip 2000 Gun Lube to treat the weapons after cleaning. The benefit of Slip 2000 Gun Lube providing superior lubrication for a high number of rounds is well known and documented. However, another huge benefit is that it keeps carbon, lead and copper from building up and ultimately makes the next cleanup time faster and easier.

The first time a gun went through this system it took a 15 minute ultrasonic cleaning cycle to fully clean it. Additional cleanings with this system on a gun after being treated with Slip 2000 Gun Lube (which meets MIL-PRF 63460E) resulted in a faster and easier cleaning. The ultrasonic cleaning cycle has been reduced to 5 minutes.

This expanded contract is testimony to the effectiveness of Slip 2000 products and the dedication of our US Military to be environmentally conscious by embracing and using GREEN products

S.W.A.T. MAGAZINE – KEEP YOUR CARBINE RUNNING

Dispelling Lubrication and Cleaning Myths

I grew up at a time when most every male had seen some military service, and I was treated to numerous tales of life in the service of this country in combat and in peacetime.

That exposure, and a strong desire to get out of the city and actually do something that mattered, led me to enlist in the Marine Corps shortly after my 17th birthday.

While I had fired rifles and pistols before, my education was informal and generally limited to what my Dad and others remembered, as well as the articles in the various gun-related magazines of the time. Cleaning was something that took on an almost formal overtone and was continued for three consecutive days.

This paled in comparison to what I was taught in the Marine Corps Recruiting Depot (MCRD), where cleaning was in fact a religion, and reached Jesuitical proportions at Parris Island. The brand-new M14s were scrupulously scrubbed on that three-day schedule, a remnant of the use of corrosive primers during World War II. No one had bothered to tell the Marine Corps that that was then, and this was now, so three consecutive days it was. Interspersed with the cleaning lectures were equally ardent lectures about why we shouldn’t believe all of the gun magazines and newspaper articles bemoaning the adoption of the M14 and how this monstrosity would lead to the demise of the Western World.

Surprisingly, when we got to the Infantry Training Regiment (ITR) at Camp Geiger, we were issued M1 Rifles, and all of the T/E equipment was what we would now consider old school-M1918A2s, M1919A4s, etc. The training schedule was all field oriented and we shot what was considered a lot (by 1963 standards). On several occasions after returning late from the cold and wet North Carolina training sites, I marched my squad straight into the shower. We scrubbed the mud off our rifles, 782 Gear and bodies. We brought the rifles into the squad bay and briefly cleaned and lubed them on the deck while using the miniscule cleaning gear that we were issued or purchased. We squared our gear away and grabbed a few hours sleep before heading off to learn something new about killing other humans.

What a great life!

I was initially terrified that we weren’t spending enough time cleaning those old M1s, but they continued to work as long as they were properly lubed and moderately cleaned. Then I began worrying that the M14s might be more fragile if they required such constant attention as taught at MCRD. How could that be? After all, they were similar in many respects, so why did one require much more cleaning than the other?

The short answer is that they don’t require a different cleaning regimen because they are different rifles-it is just that cleaning has to be looked at from several widely divergent points of view.

The first and most obvious is that, if there is sufficient time available for cleaning, that time will be used for cleaning, meaningless or not. Second is that, under exigent circumstances, a quick cleaning, paying particular attention to salient points, may be all that is necessary to keep the weapon running.

A military issue is that in many units the armorers-and sometimes even an officer-will conduct what amounts to a “white glove” inspection, wherein the troops will be kept “busy” by performing useless, and sometimes harmful, “cleaning” in order to satisfy the whims of despots and buffoons. Removing protective lubrication or scraping away finish does nothing to improve serviceability-it only destroys the guns and angers the troops.

When the M16 first came upon the scene (shortly after the M14), it was a shock to those who believed in wooden stocks, match sights and big bullets. It was billed as needing minimal cleaning, which turned into self-cleaning, which turned into no cleaning as some rifles were issued “in country” without cleaning equipment. Several issues combined to make a tolerance stack, and malfunctioning rifles were the result.

Probably as the result of these issues in the late 1960s, a myth of grand proportions has swelled up concerning the care and cleaning of the AR platform. This myth specifies that the AR must be kept spotlessly clean, and that it takes an hour (if not more) of steady cleaning for the rifle to be once more useful. Indeed, because this rifle allegedly dirties where it feeds, it must be cleaned regularly and with great care if you are to use it. Also, a few meager grains of sand will cause it to stop running.

The highlight for many errornet pundits comes when then rally around a female soldier whose convoy was ambushed during Operation Iraqi Freedom. “Remember Jessica Lynch” has become a cry of the unknowing, and while the subject makes for great points for their side, it is flawed.

Reports concerning this incident state that there were weapons malfunctions to be sure. However, a sergeant in that convoy stated that the weapons were cleaned daily and were clean when they left that morning. The M16A2 wielded very efficiently by a soldier who killed six of the enemies with it did malfunction-because of a faulty magazine and a broken extractor. This is a service-life issue with the rifle, not a design flaw. While leadership and depot level maintenance might have prevented something like this, the proper steps were not taken at a level above the soldier in the field. An M249 also failed, but that may have been due to lack of training with the weapon. And what of the celebrated centerpiece of this fight? She may have been knocked unconscious when her vehicle crashed at the beginning of the action-but this is casually brushed aside in the bubble gum (gun) forums. The serviceability of her weapon is therefore moot.

Here’s a news flash: Sand in the chamber will stop most guns-M16s, AK-47s, M24s, M1s, M9s and so forth. It is not unique to the AR platform.

Cleaning is a hot-button topic, and a great many (especially AR detractors) really believe that the AR has to be kept meticulously clean to function. While having a clean gun is never bad, neither do you have to put up with the white glove nonsense.

My cleaning regimen may be different from conventional protocol, but it works and has stood the test of time. I normally spend no more than ten minutes doing a field cleaning, and oftentimes less than that. If it takes you an hour, you are wasting time on something or you are doing something wrong.

This is the cleaning protocol that I use. This isn’t “the” way, but rather “a” way. I don’t pretend to know everything, and I wind up learning something new almost every day. Not using what is listed below won’t necessarily get you killed, make you unattractive to a potential mate nor make you unpopular at the local gin mill.

I’ll field strip the carbine and punch the tube with a wet patch. Leave the chemicals to do their work and get to the bolt/bolt carrier assemblies.

Spray the bolt with either Slip 725 or Evinrude Johnson Engine Turner and let it sit.

Clean the bolt carrier assembly by removing carbon from the bolt carrier (yeah, that chrome-lined thing where the bolt goes in) and the bottom of the bolt carrier itself. You can use a wet pipe cleaner to clean the inside of the bolt carrier key, but I rarely do. Do not put anything inside of the gas tube-it is unnecessary, and you will only stick debris in there that can do no good.

Use your toothbrush and a rag to clean the bolt, specifically the bolt lugs. Do not concern yourself with the carbon build up on the bolt’s tail. No matter how you clean it, it will just reappear the next time you shoot it. I had an armorer once tell me that the carbon promoted corrosion. That may well be if the gun is never shot, but I have yet to see a working bolt corrode away.

Attach the chamber brush to your cleaning rod and scrub out the chamber. I generally use a worn brush, wrap a wet patch around it and insert it in the chamber. Spin it a few times and replace it with a fresh brush and patch. Spin that and then dry the chamber out. Clean out the locking lugs with cotton swabs.

Spray some Slip 725 into the upper receiver and the charging handle. Your toothbrush and cotton swabs work well here.

Take a few dry patches and clean the barrel. Note that I don’t normally use a bore brush, and allow the cleaning fluid to take care of the bore.

Before the rockets start flying, let me state that I used to shoot Service Rifle, and am a High Master and a Distinguished Rifleman. I rarely used a brush on my M14NM or match AR-15s. If I felt that the bore was heavily fouled, I ran several wet patches through it, and if I absolutely felt the need for a brush, it was nylon, not copper. Never ever use a stainless steel brush in your barrel.

Understand that this is for a carbine, which by virtue of its definition is a short-barreled rifle. The 5.56x45mm service rounds and M4 carbines are certainly capable of hitting out past 500 meters, but it shines in fights that take place under 200 meters. Bothering with inconsequential increments may not be useful under these circumstances. However, if you have an SPR type, by all means give the care to that barrel that it deserves, but that care may be wasted on a 10.5-inch to 14.5-inch carbine.

Before reassembling, check your bolt rings for serviceability. Insert the bolt into the bolt carrier, and turn it upside down (preferably over something soft). If the bolt falls out on its own, you need to change the gas rings. If not, you are good to go.

Don’t get locked into the nonsense of misaligning the gas rings. The Colt Armorer instructors state emphatically that the gun will run with only one good ring, and I have done exactly that. We have been teaching that misaligning the gas rings is a waste of time for about ten years or so. I have seen nothing that leads me to believe differently.

One of the very prominent AR myths is that the gun runs better dry. It is a myth.

The AR series runs significantly better wet than dry, but there are those who approach this with such great trepidation that they steadfastly refuse to use only a tiny bit of lube on their carbines, causing them to cease functioning after a very short while.

Hundreds of e-net posts speak of using little lube on the carbines, believing that too much lube is the cause of all problems. A friend, a retired Marine MSgt and a prolific Class 3 collector, looks at lube like it was two-day old cat urine, and is absolutely phobic about putting anything more than a drop or two on any gun.

Our experience is that, after poor magazines and operator-induced malfunctions, dry guns are a major cause of stoppages. We see this in every class we have ever attended or taught, and we are satisfied that our observations regarding lubrication are correct.

Consider that your carbine is a machine, and like an internal combustion engine, it requires lubrication to make it function. There are certain wear points in the gun that need attention, and failure to do so can cause a stoppage. A good rule of thumb is to look for shiny marks, which indicate metal-to-metal contact. If it shines, get it wet.

Remove the bolt from the bolt carrier. Turn the bolt carrier over and observe the shiny area on the bottom. This is a wear point. The slot that the bolt cam pin rides in is another wear point, as is the chromed hole in the bolt carrier that the bolt rides in. The entire bolt carrier can use a coat of lube, but pay particular attention to those areas. The military also states that a drop down the bolt carrier gas key is required.

The bolt itself requires a coating of oil, paying particular attention to the bolt rings and the lugs. Those bolt rings function just like the piston rings in your car engine. How long do you think your ride would last without lube?

A properly cleaned and lubed carbine should go a minimum of 500 rounds to 1000 rounds without any cleaning at all. However, using a suppressor will cut that number down drastically, as will firing multiple rapid-fire strings or firing with the selector switch on “Group Therapy.”

I advise shooters that during the chow break they should place a few drops of oil into those two gas ports on the right side of the bolt carrier. The lube will get into the gas rings located handily nearby and keep your gun running smoothly.

Finally, a few drops of oil into the underside of the charging handle are not a bad thing.

The AR system runs much better wet than dry, and we see that during every class.

Understand that it is not the amount of lube used, but also the placement of the lube. At one class, a very experienced shooter was having functioning problems. He pulled back on the charging handle to show me that the bolt was wet, but when he released the charging handle, I could see that the area on the bolt carrier adjacent to the gas holes was dry. I placed two drops of Slip 2000 into those holes and the gun ran fine.

The moral of this story is not just to put lube on, but put it on in the right places.

Keep in mind that when at class and shooting 400-1000 rounds per day, the bolt will get blown dry. Adding oil during break time will keep the gun running and keep you learning new skill sets instead of becoming frustrated with a constantly malfunctioning gun.

In the 1990s I worked for a government agency that had a large budget. We had a fair number of guns and a lot of ammunition, so on the down days I had the opportunity to play and run some informal tests. While the exact results have been lost to the ages, some salient points remain embedded in my brain-housing group.

A totally dry gun will run approximately 100-200 rounds before seeing problems.

A clean, properly lubed gun in good condition should go from 500 minimum to 1,100 maximum.

More lube is not necessarily bad. I submerged bolt and bolt carrier assembly into a bucket of oil, shook it off and placed it into the carbine. It ran like a clock, though I only had enough time to fire off four mags worth of M855 through it.

I have used every type of lube imaginable, going from WD-40 (especially good when you have a dirty gun), to 3 in 1 oil, suntan lotion, butter and even Vagisil-don’t laugh, it works.

I may not want to use any of them for the long haul, but for a quick fix, it beats having a non-functioning gun.

The type of lube you use is something else that is full of mythology and sprinkled with fact. While the military uses CLP, a book several years ago cautioned against using it for cleaning as it “promotes carbon.” Why it only promotes carbon for cleaning and not lubricating is a mystery to me, but I don’t use CLP for anything anymore.

Commercial choices abound, from mystical concoctions of “Sergeant Major’s brew” to a host of “this is the best stuff ever made and we’ll sue anyone who says different” crap.

I prefer to stay away from most petroleum-based products, and use Slip 2000 for lube and that same company’s 725 Cleaner and Degreaser for the other chores. Slip 2000 is aqueous based, eliminating a lot of the contamination issues seen with petroleum products, and their products flat work. I have found Slip 2000 to be excellent and the owner, Greg Connor, is a great American.

If I need grease, it will be TW25B (known in the Marine Corps, where it is used on the up-gunned weapons stations on AAVs as “elephant sperm”). Mad Dog Lab’s XF7 is something else worth looking carefully at, and it appears to work well.

If you prefer to use eye of newt and toe of frog-have at it. My name isn’t attached to any of it, and if you found the absolute key to the cleaning universe, go for it.

My experience over the years as a Marine and a cop and working with sister services, foreign governments, police departments and civilians from all walks of life leads me to some inescapable conclusions.

First is that firearms are machines, and unless you keep them in the safe, heavily lubed, they will exhibit wear. Shocking but true, nothing lasts forever, and the harder you shoot it, the shorter its lifespan. Proper maintenance and cleaning will extend their useful life, but they are going to give up the ghost one day.

Just like you will.

Second is the fact that all guns are no more equal than all people are. The malfunctions that I see at military classes are the result of worn-out guns and bad magazines. In the open enrollment classes, the malfunctions I see are poor quality control on the aftermarket guns, bolt carrier gas keys not staked/staked with a limp wrist, bad magazines and improper lube.

I try not to be shocked and amazed at the poor quality guns being turned out by many, but then the homemade guns-the so-called “FrankenGuns” built with gun show parts and little knowledge-lead me to believe that in the gun world, P.T. Barnum would be a master.

That isn’t to say that all of the companies aren’t capable of turning out good (even great) guns, and often they do. But as a good friend often states, “Even a broken clock is right twice a day.” I’m not impressed with the bleats of “Well, I’ve had this gun for ten years and it has never ‘jammed’ once.” Of course not. Malfunctions only occur when you fire them. I have seen enough of most types to make me realize that the only ARs in my company’s armory are those that meet a standard.

Any gun is a machine, and once in your paws it must be properly maintained. That does not mean incessantly cleaned with obsessive fervor, but rather taking care of those particular areas that affect functioning. Keep a gun book and annotate it with a round count so you can figure out when certain parts (extractor springs, gas rings, bolts and barrels) need replacing. Replace these parts before they replace you.

Keep it lubed to reduce friction, and understand that the more you use it, the more parts need to be replaced. Accept that as a fact of life and drive on.

(Pat Rogers is a retired Chief Warrant Officer of Marines and a retired NYPD Sergeant. Pat is the owner of E.A.G. Inc., which provides services to various governmental organizations. He can be reached at eag@10-8consulting.com)

By Patrick A. Rogers

S.W.A.T. MAGAZINE – FILTHY 14

Bravo Company Carbine Goes 31,165 Rounds

THE M16 WAS FIRST PROMOTED AS A GUN THAT NEEDED NO MAINTENANCE.

While that statement proved false, a number of factors, including propellant powder and a lack of cleaning supplies and training, led to failures on the battlefield that are still being ballyhooed by muckrakers and the unknowing. They ignore the fact that the M16 is the most accurate and efficient rifle ever used by the military.

However, it is no more a perfect weapon system than the Glock, 1911, M1 rifle or any other rifle, airframe, ship or person.

Much of the noise related to this comes from unrealistic expectations such as the “one shot, one kill” nonsense that used to permeate military training, as well as poor discipline and tactics. Expending six magazines at the cyclic rate when the enemy is 400 meters away and then complaining that your carbine overheated may make headlines, but is also a sign of poor training and leadership.

Additionally, not all ARs are the same. Military weapons are held to a standard and factory Quality Control and outside Quality Assurance mean that problems are minimized.

Aftermarket makers may hold themselves to that same standard or even exceed it… or they can ignore it and substitute below-standard parts.

The latter means that some parts may not meet the mil specification for a number of reasons. This may mean Magnetic Particle Inspection and pressure testing of the bolt and barrel have not been performed, or the type of steel used for the barrel and bolt carrier group (BCG) is not up to spec.

For the average shooter, this may not be an issue. In fact, it may be smart marketing for some makers, as the average AR owner shoots their guns little, if at all.

From my perspective, I don’t aspire to mediocrity. I shoot a lot and stand behind students who are also shooting all day. I prefer to have weapons built to, or exceeding the standard, but also understand that not all users have the same needs or requirements.

But neither do I—not for one New York minute—believe that all ARs are the same.

At my company, E.A.G. Tactical, we are fortunate in that manufacturers regularly provide us with guns in order to see how they perform after a reasonable period of evaluation by students at our classes. While we have written about some for S.W.A.T. Magazine (LMT, S&W, M&P, LWRCI and Colt 6940), others have never seen the pages of this magazine.

Caveat, as we are not carrying these guns for real, we spend little time doing any preventive maintenance. We know that a properly maintained AR will function well. Our purpose here is to see how well the guns will function when left dirty but well lubed. I don’t suggest that you try this at home, especially if you are carrying these guns professionally.

While we used to see a wide variety of guns at class, the quality control of some makes is lacking. Apparently students have been reading the after-action reports on Lightfighter.net and Alumni.net, as we have started to see a swing toward those guns built to (or exceeding) the spec. The net result has been fewer busted guns and more time to better conduct training.

BRAVO COMPANY

Bravo Company USA is a relative newcomer, having entered the market in 2003. Bravo Company MFG was born in 2005 and started producing complete uppers at that time. Bravo Company USA produced a very small number of lowers in 2007, and Bravo Company MFG has been producing lowers since 2008. At this time Bravo Company does not sell complete guns, but several of their dealers do.

Paul Buffoni, the owner of Bravo Company, has built an extremely successful business based on providing quality products with excellent customer service.

We have run a number of Bravo Company guns over the past five years. While most were unremarkable in their boring reliability, one has stood out, both for the longevity of the evaluation period as well as the number of rounds put downrange.

FILTHY 14

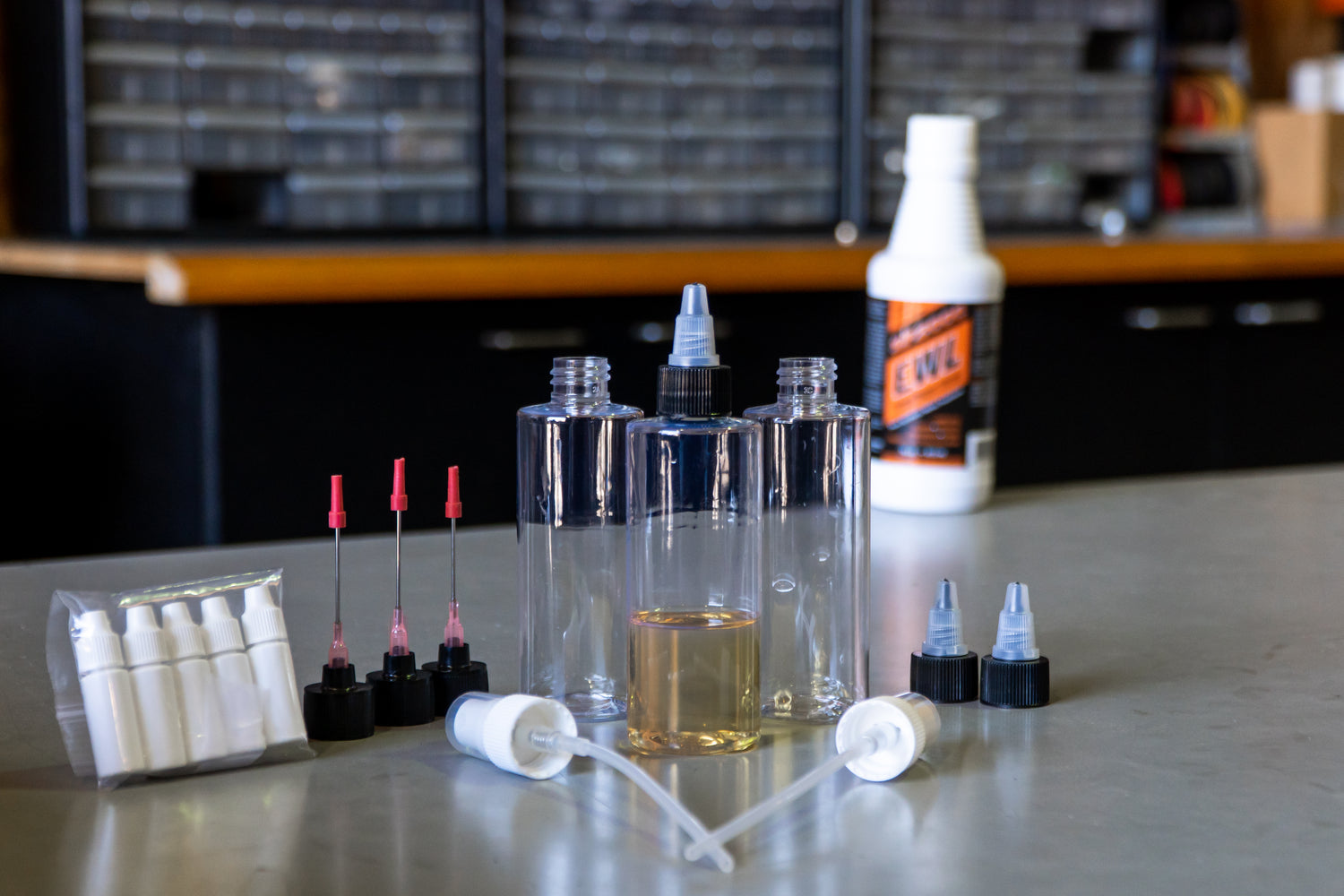

As of this writing, EAG students have 31,165 rounds downrange through Filthy 14. During this evaluation period, it was cleaned once (as in one time), at 26,245 rounds. The end result is that Rack #14 was—and remains—filthy. It is filthy because it has been shot at class. Only at class. Every round that has gone down that barrel has been fired at class, with an average of approximately 1,300 rounds every three days. It has been lubed generously with Slip 2000 Extreme Weapons Lube (EWL).

The combination of carbon and lube create (wait for it)…filth. It is so dirty that, while sitting in the rifle rack, it is almost a biohazard. The filth oozes out and contaminates other carbines adjacent to it.

But it is still shooting—and shooting well.

Rack #14 is a 16-inch Bravo Company Mid Length Carbine—mid length meaning that the gas system is two inches longer than the standard carbine gas system. This permits the use of a nine-inch rail with the standard front sight base. Use of a clamp on the front sight will permit a longer rail to be used.

The longer rail is necessary to accommodate some shooting styles, as well as to provide additional rail estate for the various white lights and IR lasers required to kill bad guys at night.

Subjectively, the mid length system has a softer recoil impulse.

The lower receiver is a Bravo Company USA M4A1, one of very few in circulation. It has a TangoDown BG-16 Pistol Grip. An LMT Sloping Cheekweld Stock (aka the Crane Stock) rides on the milspec receiver extension, as does a TangoDown PR-4 Sling Mount.

The upper is a BCM item, with a milspec 16.1”, 1:7 twist barrel. The barrel steel is chrome moly vanadium (CMV) and certified under milspec Mil-B-11595E.

The BCM bolt is machined from milspec Carpenter 158® gun quality steel, heat-treated per milspec, and then shot peened per Mil-S-13165. Once completed, each bolt is fired with a high-pressure test (HPT) cartridge and then magnetic particle inspected (MPI) in accordance with ASTM E1444.

The handguard is a LaRue 15-9, the nine-inch model to allow full use of the available rail estate.

We have a TangoDown BGV-MK46K Stubby Vertical Foregrip. We use TangoDown BP-4 Rail Panels.

The primary sight is an Aimpoint T1 in a LaRue 660 Mount. The T1 is still on the same set of batteries, and it has never been shut off. The back-up sight is the Magpul MBUS and the sling is the Viking Tactics VTAC.

This is a normal configuration for our guns, although stocks (Magpul CTR, Vltor I-Mod), BUIS (Troy), and day optic (Aimpoint M4s) may be substituted.

IN SERVICE

We received the carbine in late 2008 and put #14 into service shortly thereafter.

At Brady, Texas, in March 2009, it suffered a malfunction, which was reduced with Immediate Action. The bolt was wiped down at 6,450 rounds.

At Prairie du Chien, Wisconsin, in May 2009, it had several failures to extract, and the extractor spring was replaced at 13,010 rounds. This is far beyond the normal extractor spring life under these conditions.

At Wamego, Kansas, in June 2009, two bolt lugs broke at 16,400 rounds. We replaced the BCG. Considering the firing schedule, this is within normal parameters.

At Columbus, Ohio, in November 2009, we had several failures to extract at 24,450 rounds. The shooter gave it a field cleaning and replaced the extractor and extractor spring.

At 28,905 rounds, we finally cleaned Filthy 14. As part of our year-end maintenance schedule, we inspect and replace parts as necessary. Filthy 14 looked like the inside of the crankcase of Uncle Ed’s ’49 Packard. It was disgusting to look at and contaminated everything near it, somewhat like the toner cartridges for old printers.

I plopped it into a parts washer filled with Slip 725 parts cleaner, and 20 minutes later it was clean. Mostly clean, anyway.

We have never used a bore brush in the barrel of this gun. We did run a patch down the barrel twice, but that was all. At 50 yards it still shoots two-inch groups, and we understand that it might not at 100 yards and beyond, but we are happy with the fact that, even at 50 yards, the gun is capable of tighter groups than most of the people running it.

We have never used a chamber brush in this gun either. We were often told that this was an absolute must.

Sure…

At the last class in Casa Grande, Arizona, at approximately 30,000 rounds, we had several failures to extract. We replaced the extractor spring and wiped down the BCG.

By the time you read this, we’ll likely have another 3,000 to 4,000 rounds through Filthy 14. At that point we’ll probably retire it. We’ll reuse the LaRue rail, the sights and, after rebuilding the lower, and replace that old and well-worn mid length upper with something else.

Fourteen will continue, but just not as Filthy 14.

WHY WE DID IT

What was the point of this 15-month exercise? We know than an AR built to the spec will run more reliably for a longer period of time than a hobby gun. We have run a number of guns to over 15,000 rounds without cleaning—or malfunctions—as long as they were kept well lubricated. And because we have over 20 Bravo Company guns in the armory, we also understand that the quality of one is not an accident.

My background of belonging to a tribe where weapons cleaning approached Jesuit-like fanaticism caused me to once believe that the AR must be spotlessly, white-glove clean in order for it to run.

We know that is patently false, and in fact the overzealous cleaning regimen—clean for three days in a row, use of scrapers on the BCG, attaching chamber and bore brushes to drills, etc.—is harmful to the guns.

We know that not all ARs are the same, and only a fool believes that “parts are parts.”

If you want something that is visually similar to what the military uses, buy just about anything and you’ll be satisfied. But if you are going to use it for real, buy something that is made to the spec.

Have realistic expectations. No gun—or car, plane, hibachi or person—lasts forever. Recently a customer sent an upper back to Bravo Company complaining that the gas tube was bent.

It sure was. It was bent because the owner apparently fired 600 rounds downrange in full auto, causing the gas tube to melt into the barrel. If you want to be stupid, buy a lesser quality gun and save yourself some money.

Again, let me repeat the caveat. If you are carrying a gun for real, you need to be looking at it every 5,000 rounds or so. But if your cleaning takes more than 10 to 15 minutes, you are wasting your time on nonsense.

At a carbine class in Colorado last year, one-third of the carbines used (eight of 24) were Bravo Company guns. The fact that the Pueblo West classes are populated in large part by professionals means that this may be a clue.

CONCLUSIONS

The fact that Filthy 14 ran so long and well can be attributed to the following:

First is the design of the gun. Cpl. Eugene Stoner knew what he was doing.

Second is the quality of this particular gun from Bravo Company. Paul Buffoni knows what he is doing.

Third is the fact that we used Slip 2000 EWL which, based on past evaluations, keeps guns running long after other lubes have rolled craps. It kept the gun lubricated and made it easier for those rare times when we did clean it. Greg Conner knows what he is doing.

Finally we had a great group of volunteers who took the time to aid us in this evaluation. Bravo Zulu, guys!

(Pat Rogers is a retired Chief Warrant Officer of Marines and a retired NYPD Sergeant. Pat is the owner of E.A.G. Inc., which provides services to various governmental organizations. He can be reached at eag@10-8consulting.com)

By Patrick A. Rogers

EWL vs CLP Testing – Greg Sullivan Comments

To help add to this lubrication test, I personally built the SLR15 Rifles for this study and they were built not within our norm, as I built the rifles totally lubricant free and there was no break in or stress testing. The barrels had been antiseized upon mounting, but all parts were sent out completely dry and free from all oils, grease and lubricants. We usually do a lubrication, break in of 100rds and destressing, then clean and relubricate all parts before sending rifles out, so this test shows true insight of wear and corrosion issues that may arise with CLP versus Slip2000.

We have been using Slip2000 products for a guess of 9+years. Greg Conner will tell you that I was a hard sell, Greg took some rifles that we had been running on a range at a rifle conference, these guns were very dirty as they had just come off the range, he put the bolts and piston rods from them into a jar of Carbon Killer/Cutter, and sprayed a few other parts with 725-Degreaser/Cleaner, after about 10-minutes of conversation he pulled the parts out and wiped them clean, I was hooked.

In 2003 I was at the STI/American Handgunner Championship, and got to spend a day with Rob Latham doing nothing but shooting. I fired a guess of 1500+ rounds through a out of the box Glock-34 that was lubed with Slip2000 lube. It was 117 degrees in the desert heat, the gun was so hot I could barely grasp it long enough to rack the slide without burning my hands. But the gun didn’t miss a beat all day, at the end of the day the gun was still wet as the Slip2000 did not burn off. When I got back to MN we ran a test on a Beretta-92 that we lubed with CLP, of which would malfunction around 200-250rds consistently as the lubricant would burn off. We ran the same pistol on Slip2000 lube and at 3850rds we had to stop due to lack of ammo left at the range. The gun ran flawlessly and the Slip2000 lube was still wet.

We have been using Slip2000 lube and cleaners for many years in our armorer courses. We send out a bottle of Slip2000 EWL with every SLR15 rifle that we sell. This winter I was out in -21 degress and had the chance to shoot several SLR15 rifles, Glock-17 & 21, 9mm MP5, Remington 870 and Benelli M190, all had been lubed with Slip2000 EWL, all the weapons ran flawlessly. I was hoping to get a colder range day but missed it while I was basking in the summer like weather in Orlando at ShotShow.

I have found the Slip2000 lube and EWL to be great at corrosion protection, as our weapons here in the cold get a workout going from warm squad cars to outside in subzero conditions. The guns sweat and will rust rather quickly if not treated well, and the Slip2000 products are good to go as I haven’t had any weapons rust after switching to Slip2000 lubes. Slip2000 products are highly recommended by me personally and all of our staff, great stuff!!!

CY6 Greg Sullivan “Sully” SLR15 Rifles

Pat Rogers 8000 Rounds Letter

I posted this on another forum. Since March this gun has been shot in cold, dusty, hot duty, hot windy, freezing rain, warm rain, 134 degree temps and high humidity etc.

I have been using Slip 2000 since he started making it. Likewise I have been using the Slip EWL since he first had it in unmarked bottles. There are some really good lubes floating around. This works best for what we do.

I pretty much despise cleaning an AR. Always did, always will.

I have several BCM uppers (the best service grade upper you can buy), and decided that as I am going to take one to a class next week, and not wanting to be “That Guy”, I figured that I maybe oughta’ should douche this one out a bit. I took a look at the gun book-8070 rds. I field cleaned it once- at the 3600 and change round count. I replaced the bolt rings at about 6000 rds, so I probably wiped the bolt off a little then (BCM bolt and carrier as well).

I lube generously with Slip Extreme Weapons Lube. I’ve been using the EWL since it came out two years ago. I haven’t seen anything to change my mind.

No malfunctions… None…. Nada….

I actually cleaned the gun this time. Put a wet patch down the barrel for the first time. Scrubbed the chamber (did that at 3600 rds). The gun was dirty, but not as much as you would expect. Most of the gunk wiped off with a paper towel. The interior of the bolt carrier was a tad grungy, but some 725 and Q tips solved that.

Total cleaning time was about 10 minutes. I say “about” because UPS and FedEx (2x) visited me within a 15 minute period, so I am not exactly sure how much time it took. But it wasn’t too long.

Understand that I don’t recommend that you do this, and if I were taking this gun to war, I might see some more regular cleaning as being a good thing. However, good gun (the result of good parts and good assembly), good ammo, good magazines and sufficient lube applied often is a whole lot better than a hobby gun with an Acme parts kit, offshore ammo in “beater” magazines, and using the Secret Lube Of the Universe #27K, 2 drops at a time, in alternate months ending in vowels.

Your mileage may of course vary. But I’m looking at my four other primary carbines gun books, and they are all at about the same round count/cleaning cycle… ”

S/F

Pat Rogers EAG Tactical Training

Side by Side Review of Slip 2000 EWL and CLP

Pat Rogers’ Side by Side Review of Slip 2000 EWL and CLP

About 18 Months ago Greg Conner (Slip 2000) asked me to do a side by side of EWL with CLP. Greg Sullivan (Defensive Edge) provided two of his SLR15 carbines so we would have a standard by which to compare the lubes.

We started out with bone dry new guns then lubricated them properly. We handed the guns out to students at class and ran them through 4 classes.

We needed to apply CLP to that gun at approximately 400 rds. At 2000 rds we reapplied lube to both guns.

As we approached 4000 rds, the Slip 2000 EWL gun was still running and the CLP gun was starting to get sluggish.

No problem so far. I took the guns and put them back in the case. And promptly forgot about them.

Last week I was in the armory and found the guns. What we saw was interesting, and worth reporting.

The EWL gun was very dirty, with a fair amount of carbon. However, the bolt was still moist. The action cycled easily and nothing was askew.

When I went to the CLP gun, the bolt was locked to the rear. We could not move it. Not at all. I called up Chad M (aka BoreBrush) an armorer for a fed agency and asked him to take a look at it. He got the bolt forward, but told me it was a mess.

That was an understatement.

The bolt was bone dry and solidly caked with carbon. The wear areas had some rust. I could not remove the firing pin retaining pin nor easily move the bolt within the bolt carrier.

I soaked the bolt in my washer tank of Slip Carbon Cutter (Carbon Killer) for 10 minutes. I took a cleaning brush and scrubbed the outside of the BCG. A pair of needle nose pliers removed the firing pin retaining pin and I disassembled the bolt.

Ten minutes later and after some tooth brush scrubbing, paper towel wiping and q-tip twirling, the BCG was GTG. I cleaned the upper receiver, lubed everything with Slip EWL and reassembled the carbine.

Later I cleaned the Slip gun. This one took less time as it was not as hard baked on.

I know, Pat cleaning a gun? Cleaning two guns? In one day! The world may indeed spin off of its rotational axis and we are all soon to be doomed…

Lessons Learned:

(head smack) Guns that are constantly used can skip cleaning. Those that are used hard need to be cleaned before being stored.

The legions of myth re-tellers who claim that carbon causes pitting may not have a clue, or may never actually witnessed this. While we saw some rust on the (formerly) shiny areas, there was absolutely no pitting on the bolt or bolt carrier. None. Nada. Nuthin’….

Slip works. Let me say that again. Slip works. Period. Better than any other lube I have ever used.

Slip Carbon Cutter (Carbon Killer) works like a bandit. Big Time.

The DI system is far from dead.

The AR does not need to be white glove clean. It does need to be wet.

Many thanks to Greg Conner (Slip 2000) and Greg Sullivan (Defensive Edge). Read Greg Sullivan’s comments about the test here. Thanks to Chad M for showing me something new.

I don’t recommend allowing any guns to go too long without cleaning. I certainly don’t recommend letting a duty gun get this dirty. I allow this because my days of hunting people are long over, and my purpose here is to see how guns run when used hard, and not pampered.

Colt 6940 with 15,000+ Rounds

The Colt 6940 now has 15,000+ rds downrange, and the only issue so far surfaced here on T1 when an over enthusiastic “PUSH” resulted in a PMAG over traveling the mag catch.

This gun has not been cleaned, and has only been lubed with Slip 2000 EWL.

Pat Rogers

1/69 Infantry Thanks SLIP 2000

The “Fighting 69th” 1/69 Infantry NY National

Just wanted to send a quick update. Our rotation is coming to an end. Thanks to the SLIP products and regular maintenance we have not experienced a weapons malfunction. We really appreciate your help and support. Attached is a photo of some of our unit taken in front of our FOB. The green flag is our unit flag – 1/69 Infantry.

Just a bit about us, we are all from the 1/69 Infantry NY National Guard (the “fighting 69th”) which is based out of New York City and Long Island. We were here in Afghanistan for about a year as part of Joint Task Force Phoenix helping to mentor the Afghan Army and Police.

Being form the NYC area we all are very focused on the job to be done over here. We have been using the SLIP products on our M4 carbines, M9 Pistols, M249 Saw¹s, M240 7.62mm Medium Machine Guns and our Browning M2, 50 cal Heavy Machine Guns. We have tested all in combat except for the M9 with no problems due to lubrication. This is a pretty harsh environment with the heat and dust/dirt, but your products are doing the job.

Keep up the good work!

Thanks again, Seth Baxxxx Camp Dubs, Sector C 2-101 Cav, 27th BDE, Darulamon

PRECISION SHOOTING MAGAZINE

PRECISION SHOOTING MAGAZINE An Arduous Journey Through the Lilliputian World of Lands and Grooves By Irv Benzion Vol. 53 No. 9 – January 2006

The arduous journey through the “Lilliputian World of Lands and Grooves” started nearly three years ago. As the journey began it was believed to be just a short lackadaisical romp, but that belief was short lived. For as we proceeded, vast new vistas of knowledge appeared, taking one this way and that down the avenues of discovery. In truth this article was written, rewritten and rewritten again and again over a three year period as new advances in the chemistry of bore cleaning compounds appeared on the commercial market.

Our instrument of discovery a Hawkeye® Bore Scope and our pot of gold, Slip 2000, and Bore Tech miracle products. What made the pilgrimage possible was a Gradient Lens Corporation Hawkeye® Bore Scope. For the first time, the inside of a barrel became visible to the naked eye. For the first time, the smears on a dry patch did not have to be examined and evaluated – for now one could actually see if the rifling was truly clean.

Our odyssey begins in the late spring, 2003. After check-firing a number of varmint rifles that were to be taken on a week long jaunt to Montana after prairie dogs, the tedious job of cleaning was begun. Glancing up from the eye piece, and turning towards Moe Scharhon, one of my shooting and hunting partners, I remarked in an exasperated tone, “It’s still not clean!” Our accepted routine of cleaning had been performed, but smears of copper and layers of black carbon still remained visible in the rifling.

My involvement in the cleaning of firearms is not due to enamored interest in the process, but due to a desire to make the rifles shoot as accurately as possible. For me, shooting is fun – cleaning is work! So the best – read that the fastest, and easiest way to clean a firearm – is the true goal.

A Hawkeye® Bore Scope had been sent to me for evaluation by Ken Harrington, Gradient Lens’ Reseller Manager. I was so impressed by that first encounter with the Bore Scope at the range the following day a call was placed and credit card numbers were given. I simply had to own one. To say that the Hawkeye® has excited my imagination and lent a desire to let others know what a superb addition it is to any shooter’s collection of cleaning implements is a major understatement.

Returning from the Montana hunt, the rifles were set aside, as an extraordinarily fine summer concluded in the Pacific Northwest, and family involvements intervened. The “dog” rifles sat beckoning, so with the coming of the fall rains, and the recruiting of Moe and my other hunting partner, John Barnett, a plan was developed to determine the effectiveness of every bore cleaning solvent we could lay our hands on, and to reevaluate the techniques used in the cleaning process.

The battery of rifles waiting to be cleaned consisted of five .223s, four .22-250s, two .220 Swifts, and a 6mm Remington, most having been shot between 200 and 300 times. There were exceptions of course, as two of John’s rifles topped the “dirtiness scale” with over 1200 fired rounds fired, each. Also to be cleaned was a semi-automatic belt fed .308 Browning 1919A4 that had had over a 1000 rounds down its tube at a rate which made the barrel shroud way too hot to touch.

The cleaning regimen decided upon was to first wet the bore with two patches soaked with one of the many name brand petroleum based bore cleaning solvents on hand. That was followed by a 50 to 75 strokes with a bronze brush, after which the solvent was allowed to stand for 5 minutes. Finally the bore was dry patched. Then each bore would be checked visually with the Hawkeye®.

If copper was found to be present, a couple of patches soaked in copper solvent would be pushed through the bore and the rifle set aside for five minutes to allow the solvent time to work. If instead the inspection showed a evidence of carbon fouling, the bore cleaner was reapplied. The process would be repeated as many times as necessary, depending on which type of fouling was found lingering in the bore. In some cases, as many as ten repetitions were necessary. When it appeared that all of the fouling that could be removed chemically was removed, J B’s Bore Cleaning Compound was applied to a used bronze brush and was scrubbed back and forth in the bore 50 to 75 times. At which time bare metal would usually appear.

As can be seen, to get a firearm’s rifling truly clean is real drudgery!

After the cleaning gala was concluded, curiosity continued to nag at me to persevere in the search for new chemicals that would make cleaning a rifle a lot less work. In the months following the three day cleaning jamboree a plan was conceived. In January the SHOT SHOW (Shooting, Hunting, and Outdoors Trade Show) would be attended with the mission to solicit every new cleaning solvent found for testing.

But first let’s discuss the unit that provided the venue to enable the discoveries of our miniature land to become evident.

The Hawkeye® Precision Borescope

The Hawkeye® model that was purchased was the 17 inch deluxe version, complete with angle eyepiece and carrying case. Although one can get along without the angle eye piece, its use eliminates the necessity of bending over or squatting down to align the eye with the borescope and hence the bore’s axis. To be able to stand upright and see the rifling of a firearm one is cleaning is well worth the angled eye piece’s added expense. The angled eye piece is easily attached to the Borescope body by merely pulling back on the finger grooved ring and snapping it into place.

The Hawkeye® consists of three components: the body which has an eye cup that adjusts so that the image can be brought into focus and to which is attached a slender metal tube. The metal “optical” tube serves two functions; it transmits the image to the eye piece and, at the same time, transmits light forward to illuminate the interior of the bore.

The second component is a hollow metal “mirror” tube which contains a very small mirror on one end and a knurled knob on the other. The “mirror” tube is simply slipped over the “optical” tube on the body and by rotating the knurled knob on the mirror tube, the reflection in the mirror permits examination of the top, bottom and sides of the rifling at any point in the barrel. The knurled knob is notched relative to the position of the mirror so the comparative position of the rifling can be determined. Protruding at right angles from the body is the attachment point for a light source. The standard light source is a modified Mini-Maglite®.

As stated by Ken Harrington, a word of caution is in order, these two tubes can be bent if not supported when inserting them into the bore and the little mirror can be broken if dropped or slammed against something hard. This is not to imply the unit is not sturdy, for it is, but care must be taken with this expensive, quality instrument.

Both the eye cup on the body and the angled eye piece can be adjusted to focus the unit. In practice the main focus on the Hawkeye® body was adjusted first, and then the adjustment tube of the angled eye piece was turned to produce a crystal clear image.

With the light source attached to the Hawkeye®, new panoramas are opened to the shooter – magnified 25 times. The sharpness of the edges of the lands were apparent, as were minute pits filled with carbon fouling found in one newer barrel. When looking forward from the lead to the muzzle on a well shot rifle, one might see the rounded edge of the lands slowly become square and sharp. Some barrels displayed tiny cuts and abrasions, both horizontal and vertical to the lands; a result of the rifling process. With little effort one can differentiate between an expensive barrel and one of lesser cost as the former’s bore is smoother with razor sharp edged lands. Fire crazing of a bore caused by hot powder gases that occurs after repeated firing and which acts as a collecting point for copper fouling was clearly evident in one rifle. (See Figure 1). In other rifles, fire crazing was observed starting at the lead and included the first couple of inches of the rifling making one surmise that this effect starts at the chamber end of the barrel and works forward. The condition of the chamber, as well as the throat, can be observed, and for the first time the very edge of the crown can be checked – from inside the barrel.

Two types of fouling

To understand the panorama that unfolds through the Hawkeye’s® eyepiece a shooter must first understand what fouling is. Basically there are two types of fouling; carbon fouling which is the result of the propellant gases created by the burning of the powder, and the smearing of copper based jacket material deposited on the rifling as the bullet proceeds down the bore.

Layers, they really do exist!

The borescope clearly proved the fouling occurs in layers. During the cleaning process one could observe a bright layer of copper which, when removed, revealed a black layer of carbon. When the carbon layer was eliminated, yet another layer of copper became visible.

It can be hypothesized that the abundance of “one step” cleaning products are a result of the purchasing choices of the shooting community who want a simple, effortless, no fuss cleaning procedure. Unfortunately, most of the combination carbon/copper cleaning solvents tested did not work as well as products designed to remove a specific type of fouling. If the product removed carbon it was usually not very effective on the copper, and vise versa.

It also saddens me to report that regardless of the current avalanche of advertising “hoopla” and the endorsement by some “big name shooters,” most gun cleaning solvents that claim to remove carbon do not work at all, or are only marginally effective.

The problem of course is how can an individual determine which of the myriad of commercial products available in the market place are effective? Without a Hawkeye® Bore Scope one can’t!

What do you see through a Hawkeye®?

The first look at a fouled bore through a Hawkeye® yields a murky image, as if the rifling were being viewed through a veil of thin smoke or the bore had been smeared with a gray colored charcoal drawing pencil. An example of a smoky visage is seen in Figure 2. Also visible in Figure 2 are light strips of copper fouling found in the corners of the grooves, and a thin coating of copper on the tops of the lands. This bore is only lightly fouled, having had only 20 or so rounds fired through it.

After the first cleaning cycle the smoky overlay is gone and, although the bore is still dirty, it has a sheen to it that can be seen in Figure 3. Additionally, Figure 3 is an excellent example of where powder fouling is interspersed with, and in some instances under the copper fouling. Note the dark, almost black, color of the multiple layers of carbon contamination, which suggests that if further shots were fired the color of the carbon build-up would darken. Also take notice of the heavy deposits of copper bullet jacket material on the right side of the photograph.

To really understand how much can be seen through a Hawkeye® borescope, examine Figure 4 closely. Pictured are examples of exceptionally dirty barrels from the 2004 Montana varmint expedition. The first three images display examples of heavy carbon fouling obscuring underlying copper layers. The fourth image is the interior of a Browning 1919A4 semi-auto barrel laden with copper after over a thousand rapid-fire rounds had been shot. Bore Tech’s new copper solvent, Eliminator was applied to the 1919A4 barrel, and all the copper seen was removed with just two applications (see section on Copper).

A heavily fouled bore is exhibited in Figure 5. This close-up shows both copper and carbon fouling spread evenly over the lands and grooves. Notice that the fouling is not built up in a specific area as in Figure 2, but is the precursor to the total black bores shown in Figure 4 which undoubtedly would occur if additional shots were fired.

And finally eureka, a completely clean bore that shines brightly from the top of the lands down to the bottom of the grooves (Figure 6). This barrel is squeaky clean! The dark area at the top of the image is caused by light reflection.

Carbon fouling

Carbon fouling is extremely difficult to remove since it is insoluble and must be eliminated by either abrasion or by the use of surfactants and detergents. The way surfactants work is to reduce surface tension and through a chemical electrical charge which breaks the bond between the carbon and the bore’s steel, thus allowing the carbon fouling to be lifted free.

A prime example of how surfactants work is dishwashing detergents. A dish is immersed in soapy water and the detergent reduces the surface tension between the crusted food and the plate and with a swish of a sponge or dish cloth the plate comes clean.

The efficacy of a bore solvent which claims to remove carbon is a function of the efficiency of its surfactant components. (Bore solvent is an oxymoron, since carbon does not dissolve.) Most petroleum based cleaners use thin oils such as kerosene or penetrating oils hoping the oil will get between the carbon and the steel bore. The results of our tests proved that most brands of petroleum based cleaners do little or nothing to aid in removal of carbon fouling.

As in “doing the dishes” a little mechanical agitation (brushing with a bronze brush) is required to effect the carbon separation from the steel and to add oxygen to help activate the cleaner. A number of the combination carbon cleaner/copper solvent manufacturers are now recommending nylon brushes as a substitute for bronze brushes for this function. The reason for this change of position is that they have received numerous complaints from customers that the copper remover part of the solvent rapidly eats up bronze brushes requiring frequent brush replacement. In my experience nylon bristles are not stiff enough to provide the appropriate level of agitation needed for carbon removal.

Before the borescope allowed close observation of the interior of the barrel, it was my belief that brushing a bore was similar to using a wire brush on a rusted piece of metal – the carbon fouling in the bore would be stripped out by a bronze brush as if it were the rust. Not so! Scrubbing serves two purposes, in that it loosens the amount of carbon fouling released by the surfactants while at the same time allowing the solvent greater access to further fouled surface area.

Perhaps the greatest error most shooters make is patching out the bore after brushing without allowing any time for the solvent to do its job. To emphasize this very important discovery let me restate it – one must allow sufficient time to for the chemicals in any bore cleaner to work. Applying a solvent, brushing and then quickly patching it out is a waste of solvent, patches and elbow grease!

Marvels of modern science

The trip to the 2004 SHOT SHOW had yielded samples of two new bore cleaners; Hoppe’s Elite Gun Cleaner and Bore Tech’s Carbon X. A major technological break-through had taken place, yet surprisingly little had been published about them. It was the discovery of surfactants that would remove carbon, and when combined with detergents into water based compound, have in my opinion, created a whole new generation of bore cleaners.

For the first time there were carbon removers available that would actually dislocate the layers of carbon fouling! Both of the “Elite” and “Carbon X” were far, far more effective carbon removers than any of the petroleum based products previously tested. Another important feature is that these two products are odorless, non-toxic, and biodegradable.

Returning from the prairies of Montana and South Dakota both “Elite” and “Carbon X” were used to clean our well shot rifles. As before, two patches soaked in the new bore cleaners were pushed through the bore, and then each bore was scrubbed with a bronze brush for 25 strokes. The rifles were then set aside to allow the bore cleaner chemicals to work for about 20 minutes. It was ascertained by testing that there was no advantage to extending the barrel “soaking” time beyond a 20 minutes.

Although “Elite” and “Carbon X” were a major leap forward in reducing the effort required to remove carbon fouling, they still required five to seven cleaning cycles to get a bore clean. Still no magic bullet!

The Pinnacle

With the coming of winter in the Northwest there was time for reloading next year’s supply of ammunition and catching up on my reading of the stacks of magazines which always seem to accumulate. So one rainy, blustery day after the New Year (2005) an ad was spotted in a magazine for a product named Slip 2000’s Carbon Cutter that claimed it would remove carbon easily. The following day a phone call was placed to purchase some of this “magic elixir.” As luck would have it the call was made around noon, so instead of speaking to a receptionist, the owner of the company Gregg Conner took my call.

I told Gregg that I wished to purchase some of his company’s products and explained that their attributes could be part of an article I was writing – if they lived up to their advertising. Gregg graciously offered to send a sample as he wanted to have his company’s products included in our ongoing investigation.

Let me state unequivocally that Slip 2000’s Carbon Cutter is the product which stands at the pinnacle in its ability to remove carbon fouling from gun barrels. At last there was a product that actually performed as claimed – it really and truly removes carbon!

In just one or two regimens it removed carbon deposits from moderately fouled bores down to bare metal. Used in conjunction with Bore Tech’s Eliminator Copper Cleaner on heavily fouled rifles, the sight of shinny lands appeared within two to four regimens.

To show just how efficient Slip 2000’s Carbon Cutter is, the AR-15 bolt from John Barnett’s rifle which had over 3200 rounds fired through it was immersed in a jar of Slip 2000’s Carbon Cutter for 20 minutes. Before the immersion of the bolt in the Carbon Cutter several of the most common and popular cleaning solvents in turn were applied. In each case none or very little of the carbon adhering to the bolt was removed.

Barnett’s AR-15 bolt was crusted and coated and appeared as if it had been dropped in wet thick mud and allowed to dry. But in this case the mud was carbon. Upon removing the bolt from the jar of Carbon Cutter, the caked on carbon flaked off when rubbed with nothing more than a paper towel.

Another test of the efficacy of Slip 2000tm’s products was the immersion of the gas piston from a Beretta 390 shotgun and a Browning Invector Plus choke tube. Again, the petroleum based cleaners were tried on the piston, to no avail. After waiting 20 minutes the piston was removed from the jar of Carbon Cutter and the fouling was simply removed with a paper towel. As shown in Figure 7, the piston was shiny right down to its plated surface.

But yet another surprise awaited! The application of a bronze bore brush to the inside of the Browning choke tube easily removed the accumulated plastic wad material clinging there.

In one heavily fouled varmint rifle it was observed that deep within the rifling at the junction where the lands and grooves met there lurked a final thin layer of burnt on carbon. Although the rest of the bore was bright metal that final layer of carbon stubbornly refused to be removed chemically. An application of J B’s Bore Cleaning Compound (available from Brownells) on a well used bronze brush was applied to finally eliminate the problem.

To answer the obvious question – a test was arranged to find out how the abrasive qualities of J B’s stack up against Slip 2000tm’s Carbon Cutter? Even after five applications J B’s failed to get a rifle’s bore down to bare metal. In my opinion Carbon Cutter had won the contest “hands down,” but J B’s was invaluable in the removal of that last stubborn carbon clinging to the corners of the grooves where chemical removal proved to be inadequate. It would seem logical to apply chemical removers first and only use an abrasive such as J B’s to remove what the chemicals could not.

In a subsequent phone conversation with Gregg Conner, the question was raised that in his company’s literature it was noted that two products, Carbon Cutter and Gas Piston Parts and Choke Tube Cleaner looked identical and were priced the exactly the same. Gregg told me that I had guessed correctly and that the two products were the same but were being marketed under different labels. It seems that Gregg, besides owning an industrial chemical company is a shotgunner and the original product was developed to clean his shotguns and chokes. Gregg further explained that the reason for the two labels was that the U.S. military and many law enforcement agencies, who are now customers, would be a little skeptical of a product labeled for cleaning shotgun gas pistons and choke tubes would work well on cannons, assault rifles and machine guns.

Lubricants

A fact to be cognizant of is that all of the new generation of carbon fouling removers are water based and are so proficient that they completely strip all imbedded oils from any metal they come in contact with. Therefore, when the carbon/copper removal phases are completed it is extremely important to apply a protective lubricant to the firearm to prevent the possibility of rusting. Notice should be taken that the word lubricant was used instead of oil. Here too there has been a major breakthrough in chemical technology that is superior to most of the petroleum-based products used by shooters.

Slip 2000tm’s Gun Lube is a synthetic, biodegradable, non-toxic lubricant. Unlike petroleum based oils which have a flash point of about 200 degrees, Gun Lube’s flash point is over 2000 degrees. What does that mean? It means that when used as the lubricant on the bolt of an AR-15, the lubricant does not burn off when the rifle is fired.

Additionally, Gun Lube does not combine with carbon to gum up and form sludge or crusting, it also does not collect common dirt, turning it into grime. Perhaps the most important gain from Gun Lube is that it enters the pores of the steel and makes future cleaning even faster and easier. This was verified by one of our tests. An AR-15 whose bore had received a coat of Gun Lube cleaned to bare metal using Slip 2000tm’s Carbon Cutter in only one regimen, this after having 80 rounds fired through it.

Copper

Copper fouling is far more easily removed than carbon fouling, as it can be dissolved in a solvent. An analogy of that would be the dissolving of a teaspoon of sugar in a cup of hot coffee. Presently, most of common copper removers contain ammonia in strengths between 2 and 7%. Ammonia is effective, but it is also a toxic chemical, has an unpleasant odor, and can cause skin irritation.

Again, a new generation of solvents has been recently introduced that are vastly more efficient, are biodegradable, non-toxic and odorless; something many spouses will undoubtedly appreciate. My first choice for a copper remover is a product from Bore Tech named “Eliminator” which puts ammonia based products in about the same class as buggy whips.

After passing an Eliminator soaked patch down a fouled bore for the first time, the patch showed a suspicious, tell-tale light blue-green color indicating the presence of copper fouling. In my experience, a blue-green color rarely appears by simply passing the first “wetting” patch of a copper solvent through a bore. Normally, a period of time has to elapse to allow the copper to dissolve before a subsequent patches display the revealing color.

My immediate reaction was that the color on the patch was a reaction between the Eliminator and the brass jag. The brass jag was replaced with a steel one to eliminate that variable, (something repugnant to the maintenance of fine rifle barrels); still the evidence of continued copper removal appeared. Eliminator solvent started doing its magic at once!

The correct way to use Eliminator is to push two successive wet patches down the bore, then allow the chemicals in the solvent an interlude of time for them to do their work. It was found that about 15 to 20 minutes on a heavy concentrate of copper was normally adequate. It was also discovered that brushing was not required as all of the agitation necessary for activation could be supplied by merely pushing the application patch back and forth down the bore “Eliminator,” which contains no-ammonia, hence has no odor, is biodegradable, does not affect the skin, and is in my opinion the most efficient copper bore cleaner yet developed.

Summing Up

For the collector, varmint hunter, or accuracy shooter, a Gradient Len’s Hawkeye® borescope is an indispensable tool. Its introduction allows visual inspection of a bore to see if it is clean and to monitor its condition. After all the years of cleaning firearms, of scrubbing, of swabbing and brushing, now for the first time the condition of a bore can actually be clearly viewed. The Hawkeye® is not inexpensive, depending on model and accessories, the price ranges from six hundred to seven hundred and fifty dollars, about the price of a fine rifle. A borescope’s value lies in that it is not only a cleaning accessory, but it also allows one to check the bore of a used firearm before purchase.

Without the Hawkeye® the discovery of the effectiveness of these new carbon and copper removers would never have been possible. These new cleaning products really do work!

The question might be raised, “What were the other products that were tested?” The names of the myriad other products used in this study have been purposely been omitted since Bore Tech’s Eliminator, and Slip 2000tm’s Carbon Cutter and Gun Lube were clearly far superior to all other products tested.

In the course of this trip through the Lilliputian World of Lands and Grooves, the Rangemaster at my home range, after having seen the borescope in action, asked me to return with the Hawkeye® to inspect a barrel he had at home, which he believed to be rough. During my return visit a few days later, as the barrel was being examined in the clubhouse, an experienced, elderly shooter observed our machinations with mild indifference.

The gentleman then began to expound on his personal cleaning methods and stratagems. He related that he cleaned his rifles immediately after firing and then re-cleaned them the next day and again a week or so later. He said that his method of cleaning had been used for a number of years, and that he knew all of his rifles were clean! He then said that he didn’t see the need to spend a lot of money on an expensive gadget. And with that last remark walked out of the door with the wave of a hand in farewell.

A few seconds latter we looked up as the door was opened and this same individual returned, this time carrying a pre-64 Model 70. “Would you check the bore on this for me?” he asked.

“Sure, glad to,” I replied. Inserting the bore scope, I asked, “Has this one been cleaned?” “Yes, it was not shot today so it is clean,” was his reply. “Well you better come take a look then,” was my answer, as the bore was pitch black and the lands were covered with a heavy layer of copper. The gentleman raising his eyes from the eyepiece and with frown covering his face said, “Where can I buy one of these?”

As was related early on in this article, after trying the Hawkeye® just once at the range, I had to own one too.

By Irv Benzion